Advanced Manufacturing

The OptoFab Adelaide hub’s facility provides researchers, innovators, and industry with a comprehensive suite of tools to drive their advanced manufacturing.

Optofab Adelaide offers complete and precise machining for a variety of materials for when complex geometries are required including the ability to work with brittle materials without causing thermal damage or stress. From medical and dental, to precision optical, engineering and aerospace, Optofab can provide the solution to your machining requirements.

5 Axis Ultrasonic and HSC Milling Flyer

Simultaneous 5-axis CNC machining

Precise machining for a variety of materials for when complex geometries are required.

Simultaneous 5-axis CNC ultrasonic machining

Ultrasonic machining is the perfect solution for soft, hard and advanced high-performance materials to avoid inducing thermal or mechanical strain.

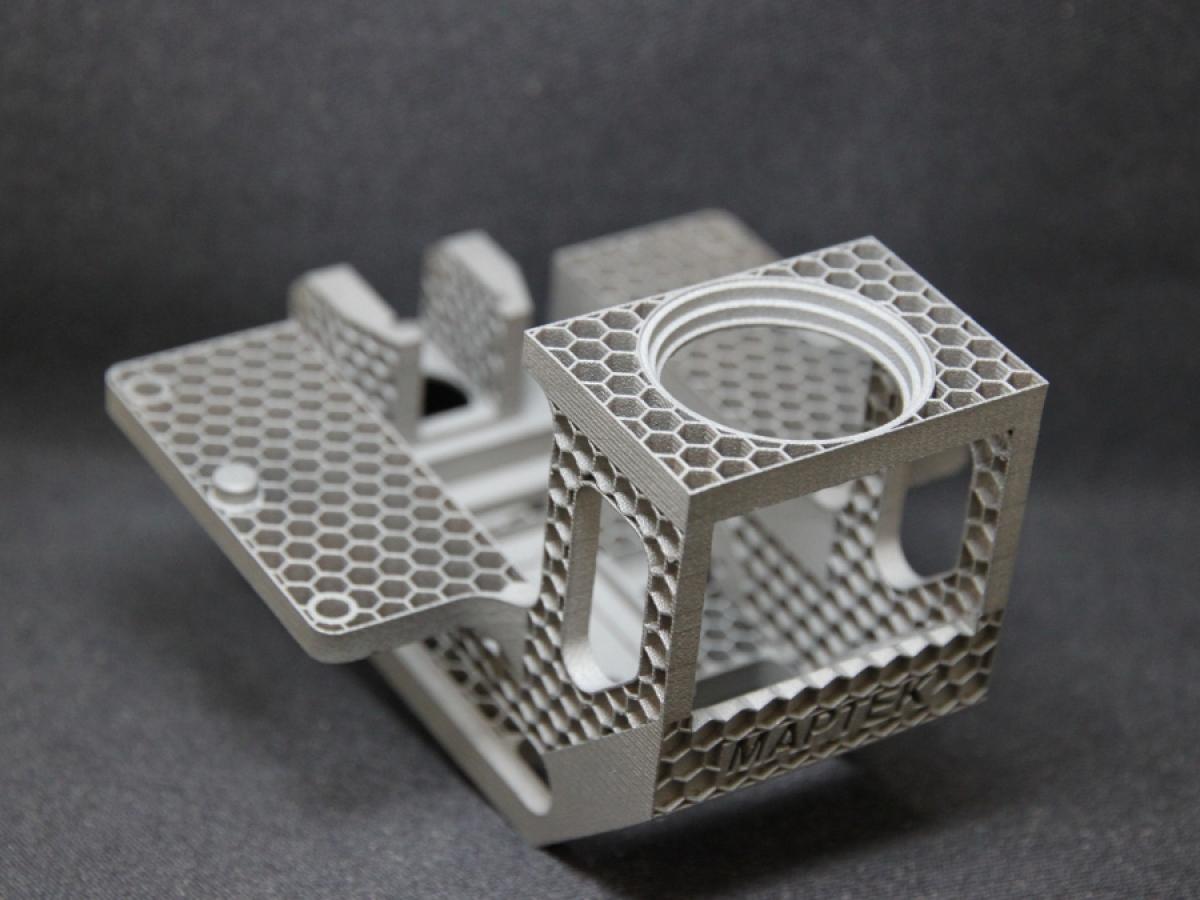

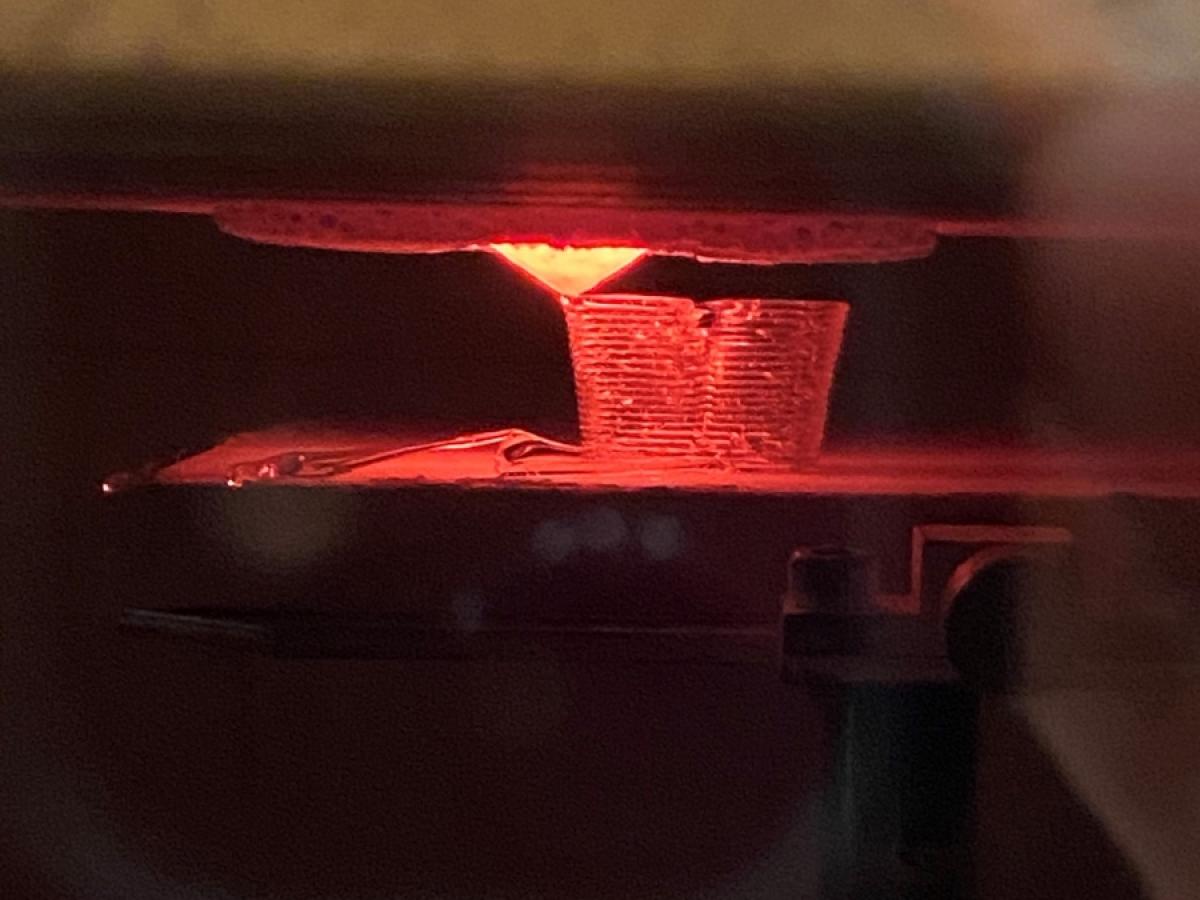

Additive manufacturing allows for the creation of complex shapes and geometries to meet specific performance requirements including high-strength metal parts.

Metal 3D printing

Print directly from your CAD drawings with a variety of metal alloys on a 3D Systems ProX200 selective laser printer.

Materials: Stainless Steel, Tool Steel, Titanium Alloy, Cobalt Chromium Alloy, Aluminium Alloy, Inconel

Polymer 3D printing

Print with a variety of polymer and silica nanoparticle-loaded resins on specialised 3D printers.

Materials: plastic, resin including specialised materials such as carbon fibre, ULTEM, ANTERO etc. Contact us for a complete list of available materials.

Glass printing

Optofab Adelaide proudly hosts Australia's first 3D glass printing capability for academic and industrial research purposes. Creating glass objects through 3D printing can revolutionise the utilisation of light and fluids in various devices.

The innovative glass materials produced using this technology have the potential to enhance energy efficiency in buildings, contribute to medical research, and facilitate the development of advanced sensors for applications in security, agriculture, and environmental monitoring.

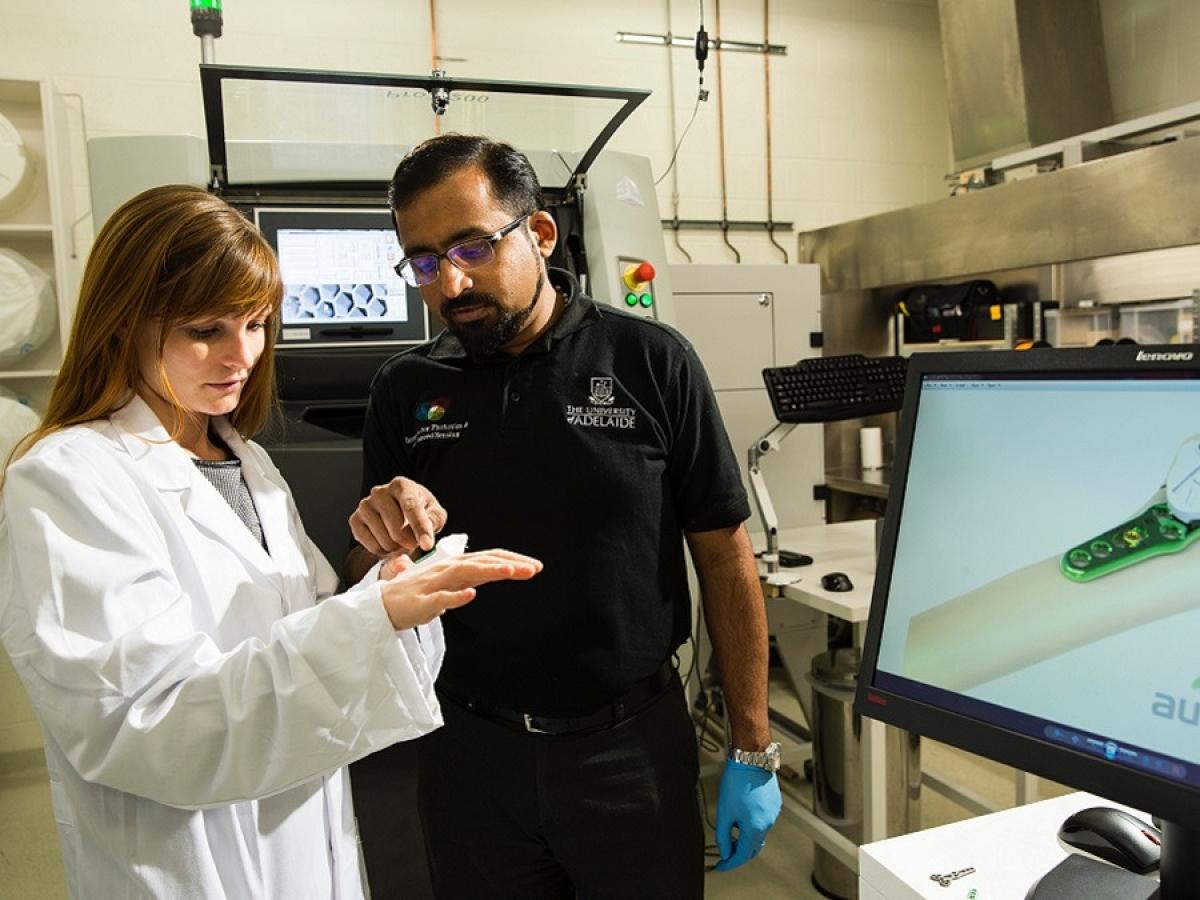

Optofab Adelaide support the development of parts, products, prototypes and more. This includes rapid prototyping techniques and access to design and simulation software for optical modelling and optimisation.

Design and prototyping

Team of specialised technicians and engineers helping you accomplish your manufacturing goals offering:

- Reverse engineering

- CAD drawing and design

- Prototyping

- 3D scanning

- Parts manufacture

Let's work together

OptoFab Adelaide work as a multidisciplinary team ready to help with any projects.