3D Glass Printing

Just as with metal or plastic 3D printers, pieces of glass can be printed from a digital design. Thanks to the Australian company Maple Glass Printing, 3D glass printing technology is now commercially available worldwide.

Glass 3D Printer

The Maple 3D printer uses cold glass rod filaments to print a digitally generated form directly into a glass object. 3D printing enables the creation of complex and intricate glass structures that were previously difficult or impossible to achieve with traditional methods.

By developing new shapes and solving material challenges with the help of scientists and expert glass artists, this technology enables glass to be used in novel ways in science, architecture, and art. It can also be combined with traditional techniques to expand creative possibilities.

-

Images Details

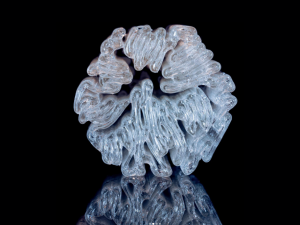

Brain Coral: Design by Brandyn Callahan and Phirak Suon. Much like how living organisms grow, 3D printing grows your design through an additive process

Dolphin Venetian Glass: The fusion of traditional and modern glass making. From the Venetian-inspired 3D printed gyroid dolphin, to the honest clarity of the blown vessel; each component works together to construct a goblet like no other. Printed with a Maple 2 & Maple 3 Ideated by Jeffrey Sarmiento.

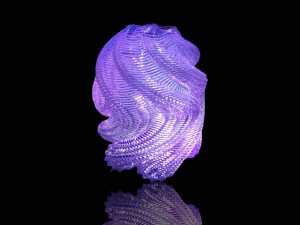

Gaffered by Yazmin Dababneh Assisted by Anna Johnson and Ethan Crawford. Thank you to Glass Art Society and College For Creative Studies Detroit for facilitating.New forms with Kugler Colours: Working with coloured glass to test compatibility and working with new single wall design for light, yet strong, design.

Architectural Experimental Glass model: An experimental 3D printed glass model (1:20 scale) of the Qaammat pavilion designed by Konstantin Arkitekter. It was developed to further analyse and demonstrate alternative construction techniques utilising 3D print glass while also highlighting variations in visual appearance, aesthetics, and transparency. 3D printing offers architects a powerful tool to create and enhance design, prototyping, and construction. More on 3D Printing Glass in Architecture with the Experimental Glass Model. 1:20

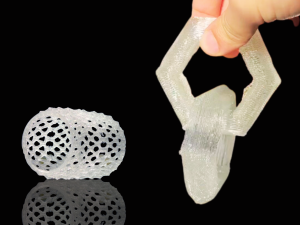

Glass Chain Links: Modelled and printed in one day, the chain and Open and Closed Lattice Structures shown represents the new versatility and speed of this new technology.

Candle Cover: From Frontier the brand: World's First Glass 3D Printed Candle Cover using glass 3D printing machine. Inspired by architecture, our designs offer more than just light – they embody an artistic statement.

New shape: Made by the ANFF-Optofab Adelaide team at the University of Adelaide, who purchased the first commercial 3D Glass Printer in Australia.

Koala: Made by the ANFF-Optofab Adelaide team at the University of Adelaide, who purchased the first commercial 3D Glass Printer in Australia.

To read on 3D glass printing and it's role in art and science: 2023 Glass Art Society Journal, Detroit

This technology supports the circular economy by allowing 3D printers to use recycled glass, turning waste material of any colour into a glass filament that can be printed into specific designs.

Although glass is infinitely recyclable, it is often not recycled due to challenges like the focus on transparent glass over coloured glass. Transparent glass is easier to process and has more uses, even though coloured glass can also be recycled.

With this new technology, recycled glass, furnace scrap, offcuts, coloured sheets and any colour bottles or glass items can be repurposed using a traditional method where glass is heated in a kiln until it becomes soft and pliable. The molten glass is then pulled through a hole, creating long, thin glass rods. This process allows waste glass to be turned into uniform rods that can be easily handled, stored, and used as filaments for 3D printing.

3D glass printing is an energy-efficient way to create glass objects, requiring less energy and safety precautions.