Cold Plasma Technology

Cold Plasma Technology is used to create a new type of antibacterial sanitiser revolutionising the health and food industry.

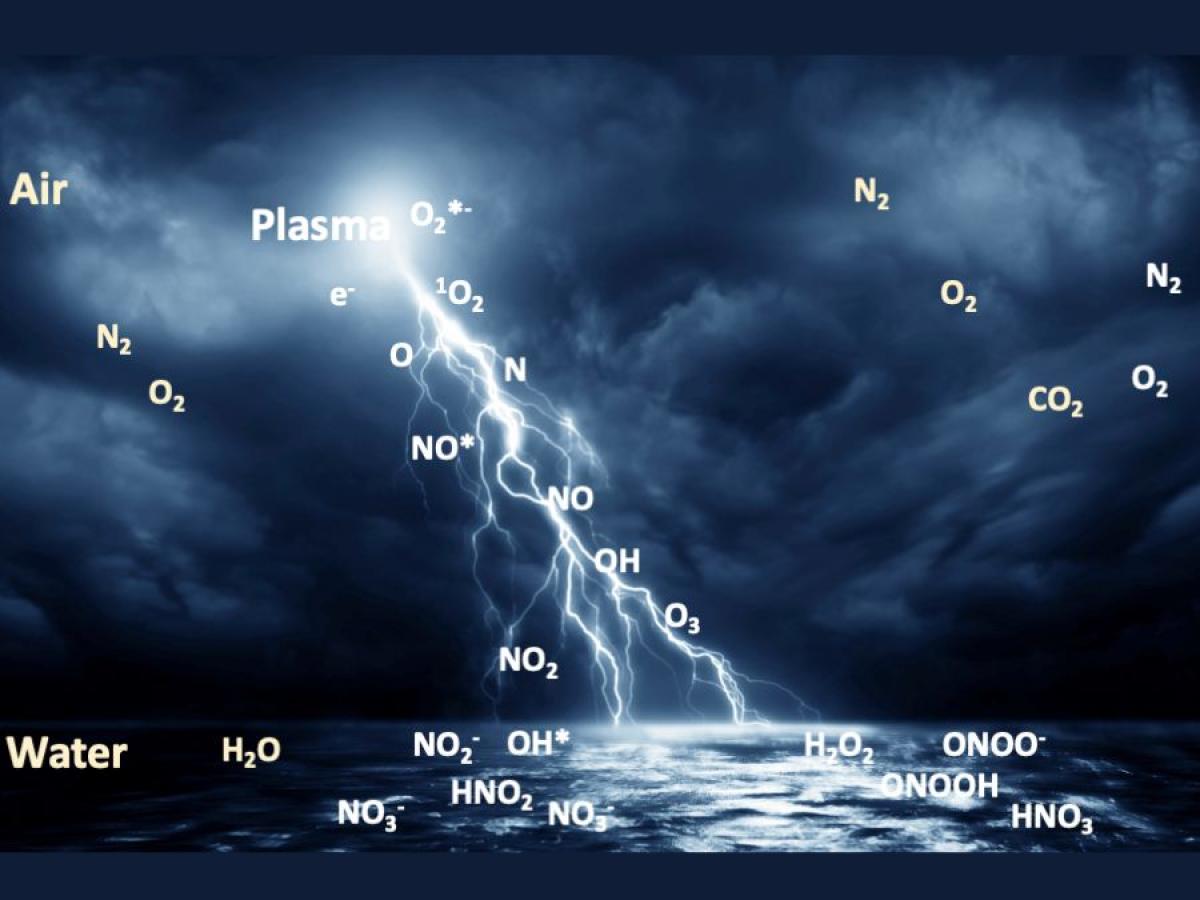

Plasma, the fourth state of matter alongside solid, liquid, and gas, is attained by infusing energy into a gas, resulting in a highly energetic state of ionized gas and reactive radicals. This natural occurrence is observable in phenomena like lightning or the aurora borealis.

In plasma, gas becomes ions as some atoms lose or gain electrons. Reactive radicals - characterised by unpaired electrons - emerge from these energetic particle interactions. Their heightened reactivity makes them effective in various chemical reactions.

The Richter lab, in collaboration with German industry partner Plasmatreat, has successfully recreated this phenomenon in the laboratory using a plasma generator. They introduce a similar plasma into water, enriching it with ionised gas and reactive radicals. This results in the creation of antibacterial water that neutralises harmful microorganisms, producing a disinfectant effect.

The sanitiser rapidly tackles bacteria, leaving behind pure water as radicals are consumed. This environmentally friendly solution generates no harmful waste, ensuring both its safety for the environment and its potential for human use.

The innovative Plasma Water stands as a groundbreaking advancement with transformative impacts on two crucial domains: Food safety and infection control in wound care.

-

Food Safety : Foodborne Superbug Slayers

Cold plasma technology has potential for applications in the food industry, proving effective in decontaminating surfaces, extending product shelf life, and enhancing overall food safety.

The use of food-grade sanitisers is a common practice in washing chicken meat and eggs before reaching consumers. However, concerns arise regarding the potential development of bacterial resistance to these sanitisers and the environmental impact of the chemicals used in the sanitisation process.

In response to these challenges, Dr Richter's team proposes a plasma-activated water solution. This eco-friendly alternative aims to provide a more sustainable defence against superbugs, significantly reducing the risk of food poisoning.

More than four million cases of foodborne disease are reported in Australia each year. Therefore, preventing harmful bacteria from reaching consumers is crucial. Food poisoning outbreaks caused by bacteria such as Salmonella could be significantly reduced if a new sanitiser is proven to be successful in the next stage of trials.

“The results of our prototype trials are really exciting and showed that our sanitiser destroyed Salmonella on chicken meat and eggs in just five seconds. We envisage that this sanitiser could be used as a spray or dip for at-risk foods such as eggs, meats, poultry and plant-based products during the manufacturing process, potentially providing a chemical-free alternative to current sanitisers and preventing disease.”Dr Katharina Richter, Lab leader, Future Making Fellow from the University of Adelaide’s Institute for Photonics and Advanced Sensing and Adelaide Medical School.

This innovative approach will not alter the taste or smell of the food and ensures an environmentally friendly process, as the active ingredients become inactivated after use, leaving behind only pure water. Embracing such advancements could lead to safer food, reduced food waste, improved public health, and potentially even save lives.

Team: Björn Kolbe (PhD student), Dr Adrian Abdo (Post Doc).

In collaboration with Dr Andrea McWhorter (Animal and Veterinary Science) and Bryan R. Coad (Agriculture and Food Science).

Industry Partners: Plasmatreat, RIBU Plasma and End Food Waster CRC. -

Infection Control : Antibacterial Wound Cleanser

The Richter lab team has showcased the capability of plasma water in efficiently eradicating pathogens in vitro while maintaining the safety of human cells. This breakthrough technology holds immense promise for advancing infection control in wound care.

Plasma water demonstrates both safety and effectiveness against biofilms formed by resistant pathogens listed on the World Health Organization's global priority list. Collaborating with Plasmatreat, the team has fine-tuned a specific plasma water formula that kills the notoriously challenging MRSA, all while ensuring the protection of human cells.

Methicillin-resistant Staphylococcus aureus (MRSA) bacteria, a resilient and dangerous pathogen.

To further validate their findings, the team plans to execute a well-established skin wound infection model in pigs, which closely mimics human skin conditions. Assessing treatment safety, efficacy, and wound healing in this model will provide insights into the potential human response. Additionally, the translation of plasma water into a first-in-human study for treating diabetic foot ulcers is slated for mid-2024, in collaboration with diabetes clinicians.

The ultimate goal is to pioneer the development of the first liquid application of plasma medicine, effectively 'storing' the antimicrobial properties of plasma in water.

"This approach promises an outstanding safety and efficacy profile, offering a cost-effective, on-demand, scalable, and storable treatment for wound healing. Such innovation will empower clinicians to optimise therapeutic decision-making at the individual patient level". Dr Katharina Richter, Lab leader, Future Making Fellow from the University of Adelaide’s Institute for Photonics and Advanced Sensing and Adelaide Medical School.

Team: Angela Boahen (PhD student), Adrian Abdo (Post Doc), Anja Zelmer (Post Doc).

In collaboration with diabetes clinicians Robert Fitridge, Guilherme Pena and Zlatko Kopecki (UniSA).Industry partners: Plasmatreat and RIBU Plasma.

In the news

SA Country Hour: "South Australian researchers hope a new food sanitiser they're developing can help prevent millions of cases of foodborne disease each year."

Publication