Photonic Materials & Optical Fibres

Prof Heike Ebendorff-Heidepriem and her team explore ground-breaking glass science and technology.

The group leads the development of the fabrication of new glass materials and fibre structures. Collaboration with externs in various disciplines and with global companies enables these glass material and fibre structures to drive innovations in sensing, non-linear optics, lasers, mid-IR and more.

Their current focus includes four key research themes

-

Research Overview

The research group has access to and collaborates closely with ANFF-Optofab Adelaide, providing them with a diverse range of expertise and facilities in glass and fibre fabrication, functionalisation and characterisation as well as advanced subtractive and additive manufacturing of metal, polymer, ceramics and glass. The research areas developed in the group range from fundamental science to application-driven design and development.

Key areas of application strength include the development of:

- Tellurite and fluoride glasses (both passive and active)

- Glasses with custom compositions

- Advanced technologies for processing and shaping glass

- Advanced preform technologies (extrusion, 3D printing and drilling based)

- Glasses and fibres capable of transmitting light in the mid-infrared that underpin new sensing platforms and lasers

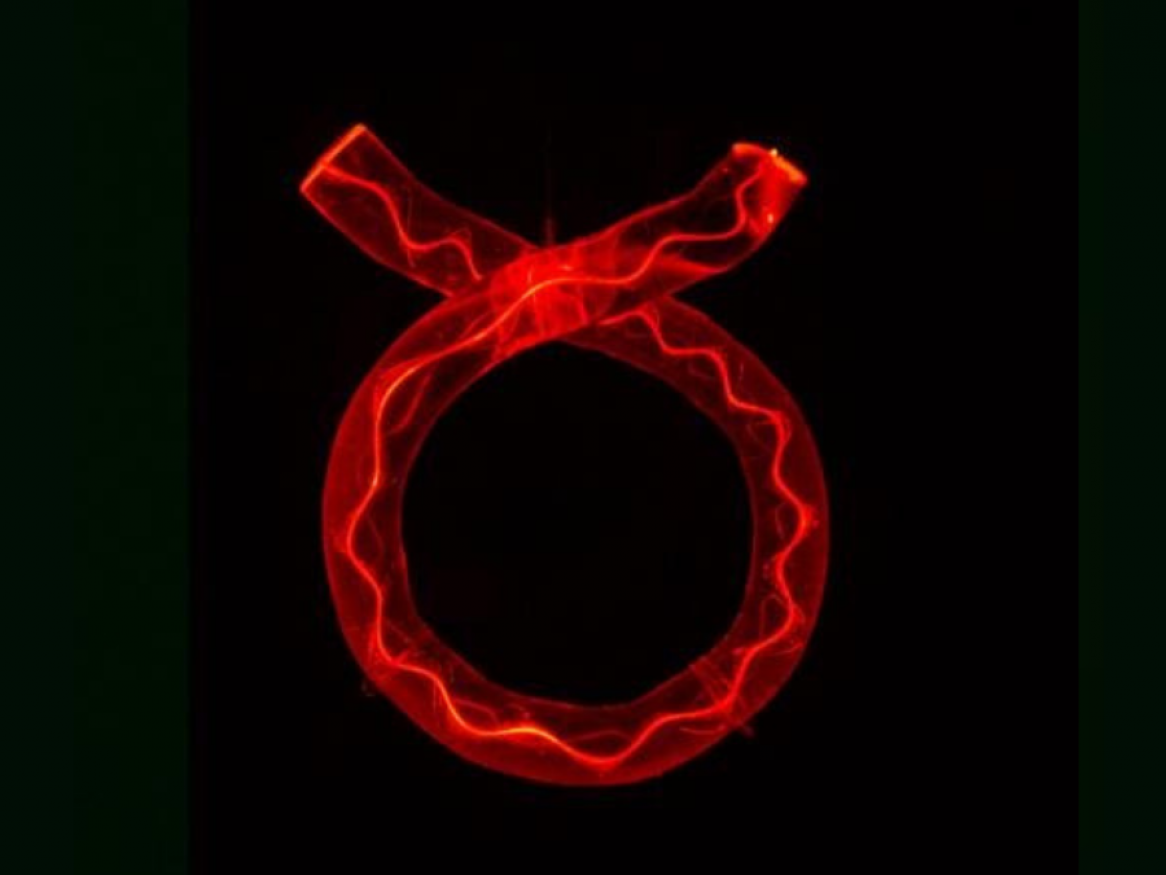

- Silica microstructured optical fibres, including suspended and exposed core silica fibres for sensing

- Soft glasses and optical fibres with enhanced infrared transmission and optical nonlinearity

- Hybrid glass fibres created by embedding nano-/micro-crystals in glass

- Microstructured soft glass fibres for sensing and nonlinear processing

- Microstructured polymer fibres for THz guidance

-

Modelling

Modelling is primarily carried out in collaboration, examples include:

- A suite of analytical, numerical and finite-element modelling tools to predict the optical properties of waveguides and fibres

- New theoretical frameworks to explore waveguides and fibres with extreme properties and nanoscale features

- Mathematical modelling of the complex mechanics of fluid flow

-

Fabrication and postprocessing of glasses and fibres

Fabrication of glasses and fibres are conducted in partnership with Optofab Adelaide. Examples are:

- Controlled atmosphere glass batching, melting, casting and annealing

- Soft and hard glass preform extrusion

- Soft and hard glass and silica preform ultrasonic milling

- Soft glass and silica fibre drawing

- Soft glass 3D printing based on filament deposition

- Silica 3D printing using silica nanoparticles loaded resin

- Splicing of soft glass and silica fibres

-

Characterisation

Adelaide is fortunate to have access to a range of characterisation facilities including:

- High-resolution optical and electron microscopes

- Transmission spectrometers and ellipsometers spanning from the ultraviolet to the far-infrared spectral region (200 nm-30 μm)

- Optical profiler to measure surface roughness

- Simultaneous thermal analysis (STA/TGA/DSC)

- Fibre loss measurement

- Optical tables for laser and optical experiments

Prof Heike Ebendorff-Heidepriem

Institute for Photonics and Advanced Sensing (IPAS)

The University of Adelaide, AUSTRALIA 5005

Telephone: +61 (0)8 831 31136

Email: heike.ebendorff@adelaide.edu.au

- Dr Anna Radionova - Extrusion

- Dr Jacob Dalgleish - Diamond

- Dr Ka Wu - ZBLAN

- Dr Yunle Wei - ZBLAN, Gold NPs

- Dr Kwang Jun Lee - ZBLAN

- Dr Heng Zheng Ting

- Dr Quoc Hue Pho

- Dr Anoop Sunny

- Asfandyar PhD - Extrusion

- Sachin Kumar PhD - Diamond

- Ehab Salih PhD - ZBLAN